12

Selecting the right wheel can make a big difference in the performance and life of your caster. To determine

what material would work best for your application, please review the below material descriptions and

features — or connect with us at

www.albioncasters.comor

800-835-8911

for specification assistance.

SELECTION GUIDE

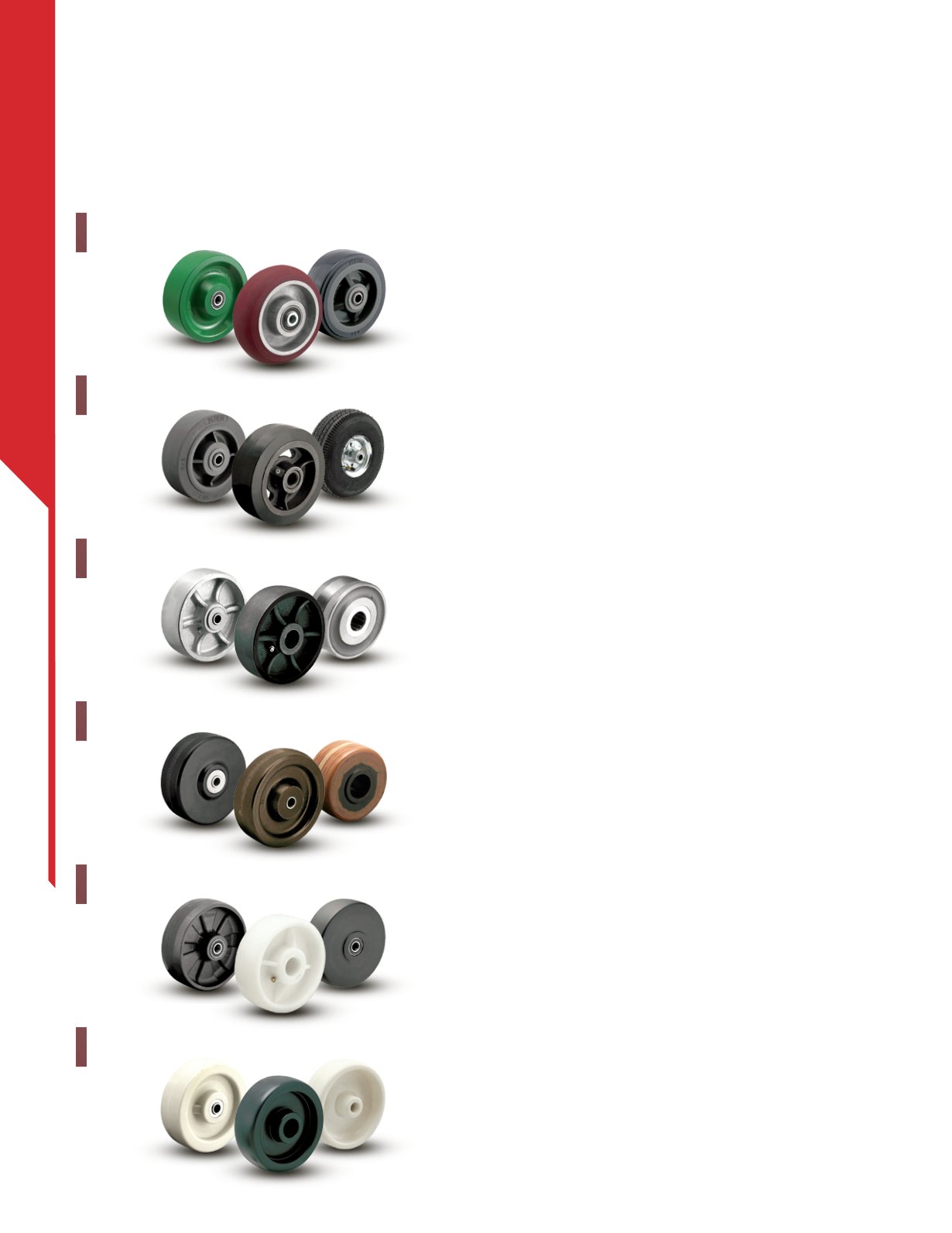

Albion’s polyurethane wheels are uniquely

formulated and open cast or injection

molded to clean, close tolerance cores.

Each unique formula is designed for spe-

cific mobility benefits, including: ergonom-

ics, shock absorption, noise reduction,

debris rejection, and overall durability.

» Non-marking, floor protective

» Resists chemicals and oils

» Excellent capacity, wear

resistance, and strength

» Quieter and more shock

absorbing than metal wheels

» Designated wheels are towable

» Various durometers, thicknesses,

tread profiles and colors available

Description:

Features:

Rubber wheels provide exceptional floor

protection, shock absorption, and our more

advanced formulas even reject metal shav-

ings and debris (X-tra Soft, MG, NP, SZ/SV).

Various options can be found throughout

our rubber wheel offering, including: non-

marking formulas, no-maintenance/semi/

fully pneumatic wheels, and a variety of

durometers and color choices.

» Floor protection

» Quiet mobility

» Cost effective

» Shock absorption

» Indoor/outdoor use

(pneumatic family)

Description:

Features:

Metal wheels offer the highest capacity,

temperature resistance, and strength for

your most abusive indoor/outdoor applica-

tions and floor conditions. Albion offers a

range of materials to best suit your applica-

tion, including: cast iron, ductile, and drop

forged steel options.

» Highest load capacities

» Handles the most abuse

» Impact resistant

» Resistant to hot and cold

temperatures

Description:

Features:

Phenolic wheels are constructed of

heavy macerated materials impreg-

nated with phenolic resins – and then

molded under high heat and pressure

to produce a quality, but economical

industrial wheel.

» High load capacities

» Resistant to chemicals and oils

» Impact resistant

» Economical

» High-temp options

Description:

Features:

Offering high load capacities and great-

er floor protection than conventional

metal or phenolic wheels, our range

of Nylon and Glass-Filled wheels are

a perfect fit for helping reduce wheel

noise or in clean applications requiring

frequent wash downs.

» High load capacities

» Impact resistant

» Corrosion resistant

» Resistant to chemicals and oils

» High-temp options

Description:

Features:

Injection molded from a blend of

thermoplastic polymers, Polypropylene

wheels are our most economical and

lightest wheel option with comparable

load ratings to hard rubber wheels.

» Most economical

» Resistant to chemicals and oils

» Lightweight

» High-temp options

Description:

Features:

Polyurethane

capacities up to 10,900 lbs

Polypropylene

capacities up to 1,000 lbs

Rubber

capacities up to 3,630 lbs

Nylon & Glass Filled

capacities up to 7,200 lbs

Metal

capacities up to 20,000 lbs

Phenolic

capacities up to 8,000 lbs

Wheel Material

WHEEL MATERIAL SELECTION

For additional wheel information

, or to see the full offering of each of these categories – please refer to

pages

130 & 131.