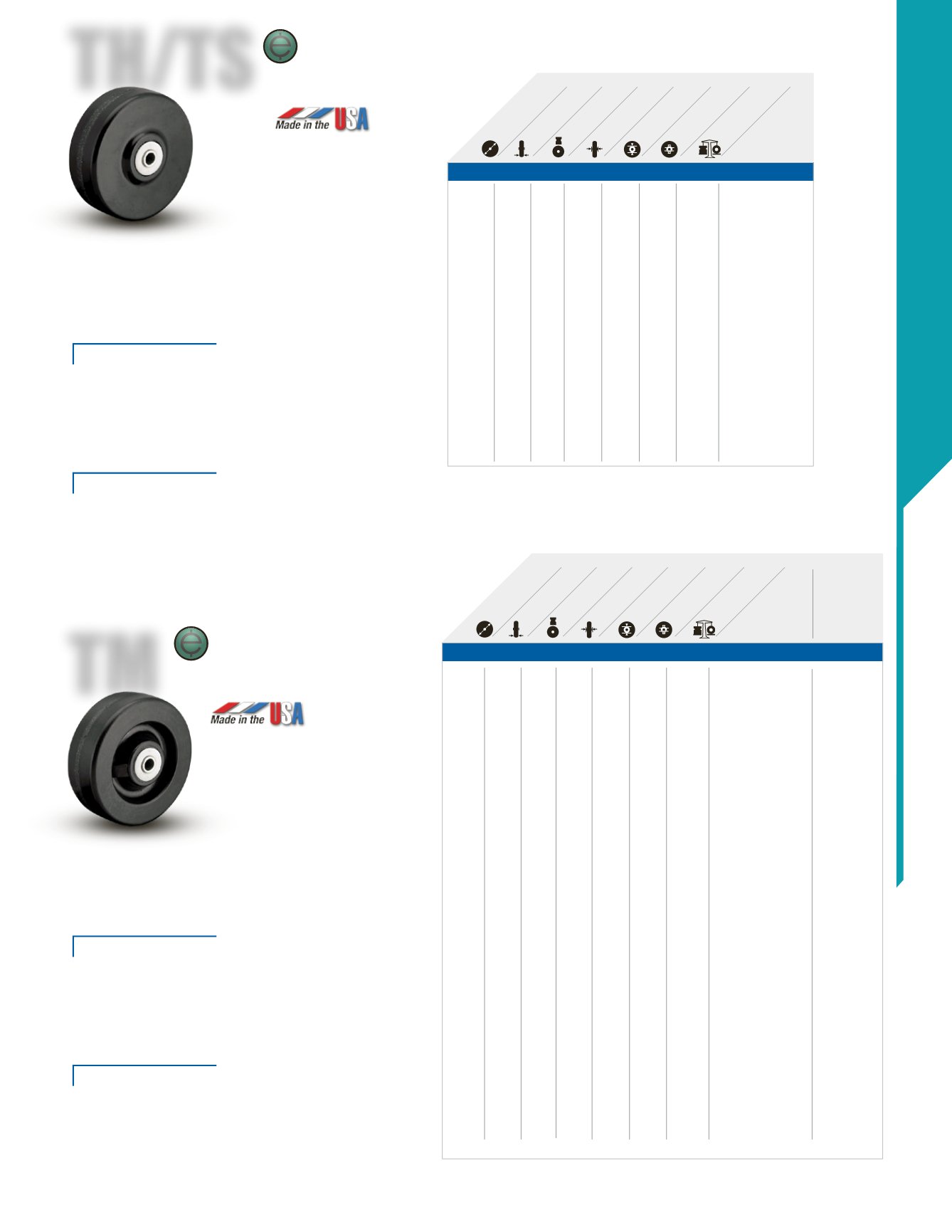

143

4 1-1/2 500 1-27/32 1-1/16 3/4 3/4

TS0410112

4 1-7/8 800 2-13/32 1-3/16 3/4

1

TS0420112

4

2 1000 2-3/16 1-3/16 1/2 1-3/4

TH0420108

4

2 1000 2-3/16 1-3/16 5/8 1-3/4

TH0420110

4

2 1000 2-3/16 1-3/16 3/4 1-3/4

TH0420112~

5 1-1/2 500 1-27/32 1-1/16 3/4 1-1/4

TS0510112~

5 1-7/8 1000 2-13/32 1-3/16 3/4 1-1/2

TS0520112

5

2 1200 2-3/16 1-3/16 1/2 2-1/4

TH0520108

5

2 1200 2-3/16 1-3/16 5/8 2-1/4

TH0520110

5

2 1200 2-3/16 1-3/16 3/4 2-1/4

TH0520112~

6 1-1/2 500 1-27/32 1-3/16 3/4 1-1/4

TS0610112

6 1-7/8 1200 2-13/32 1-3/16 3/4 1-3/4

TS0620112

6

2 1500 2-3/16 1-3/16 1/2

3

TH0620108

6

2 1500 2-3/16 1-3/16 5/8

3

TH0620110

6

2 1500 2-3/16 1-3/16 3/4

3

TH0620112~

8 1-7/8 1400 2-13/32 1-3/16 3/4

4

TS0820112

~ Wheels are complete with spanner bushing and nylon sealed retaining/thrust washer.

•

Wheel face:

Moderate crown

•

Finish:

Black

•

Temperature Range:

-65°F to +250°F

(+300°F intermittent)

•

Hardness:

Rockwell 102 E

•

Note: Select bearings featured are recom-

mended for standard applications. For special

applications or alternate bearings consult

factory. See bearing information on page 13

•

For customization & special application options,

please consult factory

TH/TS wheels are molded of heavy macerated or

chopped cotton denim, impregnated with phenolic

resin and formed in close fitting molds under high

pressure and temperature. They are non-marking

and excellent load carriers.

Straight Sided Phenolic

3 1-1/4 400 1-3/8 1-1/16 1/2

1/2

TM0300108

3-1/4 1-1/2 600 1-5/8 1-3/16 1/2

3/4

TM0310108

3-1/4 1-1/2 600 1-5/8 1-3/16 5/8

3/4

TM0310110

3-1/4 1-1/2^ 600 1-5/8 1-3/16 3/4

3/4

TM0310112

~

3-1/4 2

700 2-3/16 1-3/16 1/2 1-1/4

TM0320108

3-1/4 2

700 2-3/16 1-3/16 5/8 1-1/4

TM0320110

3-1/4 2

700 2-3/16 1-3/16 3/4 1-1/4

TM0320112

~

3-1/2 1-1/4 400 1-3/8 1-1/16 1/2

3/4

TM03X0108

4 1-1/4 400 1-3/8 1-1/16 1/2

3/4

TM0400108

4 1-1/2 600 1-5/8 1-3/16 1/2

1

TM0410108

4 1-1/2 600 1-5/8 1-3/16 5/8

1

TM0410110

4 1-1/2^ 600 1-5/8 1-3/16 3/4

1

TM0410112

~

4

2

800 2-3/16 1-3/16 1/2 1-1/2

TM0420108

4

2

800 2-3/16 1-3/16 5/8 1-1/2

TM0420110

4

2

800 2-3/16 1-3/16 3/4 1-1/2

TM0420112

~

5 1-1/4 400 1-3/8 1-1/16 1/2 1-1/4

TM0500108

5 1-1/2 600 1-5/8 1-3/16 1/2 1-1/2

TM0510108

5 1-1/2 600 1-5/8 1-3/16 5/8 1-1/2

TM0510110

5 1-1/2^ 600 1-5/8 1-3/16 3/4 1-1/2

TM0510112

~

5

2 1000 2-3/16 1-3/16 1/2 1-3/4

TM0520108

5

2 1000 2-3/16 1-3/16 5/8 1-3/4

TM0520110

5

2 1000 2-3/16 1-3/16 3/4 1-3/4

TM0520112

~

6 1-1/2 800 1-5/8 1-3/16 1/2 1-1/2

TM0610108

6 1-1/2 800 1-5/8 1-3/16 5/8 1-1/2

TM0610110

6 1-1/2^ 800 1-5/8 1-3/16 3/4 1-1/2

TM0610112

~

6

2 1200 2-3/16 1-3/16 1/2 2-1/2

TM0620108

6

2 1200 2-3/16 1-3/16 5/8 2-1/2

TM0620110

~ Wheels are complete with spanner bushing and nylon sealed retaining/thrust washer.

^ 2

7

/

16

" spanner and spacers included.

**Specially machined wheel built from 2 modified 3" tread width wheels.

•

Wheel face:

Moderate crown

•

Finish:

Black

•

Temperature Range:

-65°F to +250°F

(+300°F intermittent)

•

Hardness:

Rockwell 102 E

•

Note: Select bearings featured are recom-

mended for standard applications. For special

applications or alternate bearings consult

factory. See bearing information on page 13

•

For customization & special application options,

please consult factory

TM wheels are molded of heavy macerated or

chopped cotton denim, impregnated with phenolic

resin and formed in close fitting molds under high

pressure and temperature. They are non-marking

and excellent load carriers.

Phenolic

TM

Economical

Economical

Straight Sided Phenolic (TH, TS)

Wheel Diameter

(Inches)

Tread Width

(Inches)

Capacity

(Lbs)

(Rated formanualoperation)

Hub Length

(Inches)

Bore ID

(Inches)

Approx. Wt.

(LBS)

Bearing ID

(Inches)

Wheel

Number

Roller

Bearing (01)

Phenolic (TM)

Wheel Diameter

(Inches)

Tread Width

(Inches)

Capacity

(Lbs)

(Rated formanual operation)

Hub Length

(Inches)

Bore ID

(Inches)

Approx. Wt.

(LBS)

Bearing ID

(Inches)

Wheel

Number

Roller Bearing

(01)

Wheel

Number

Tapered

Roller

(09)

FEATURES

FEATURES

WHEEL OPTIONS

WHEEL OPTIONS

Continue on next page >>

PHENOLIC WHEELS • UP TO 1500